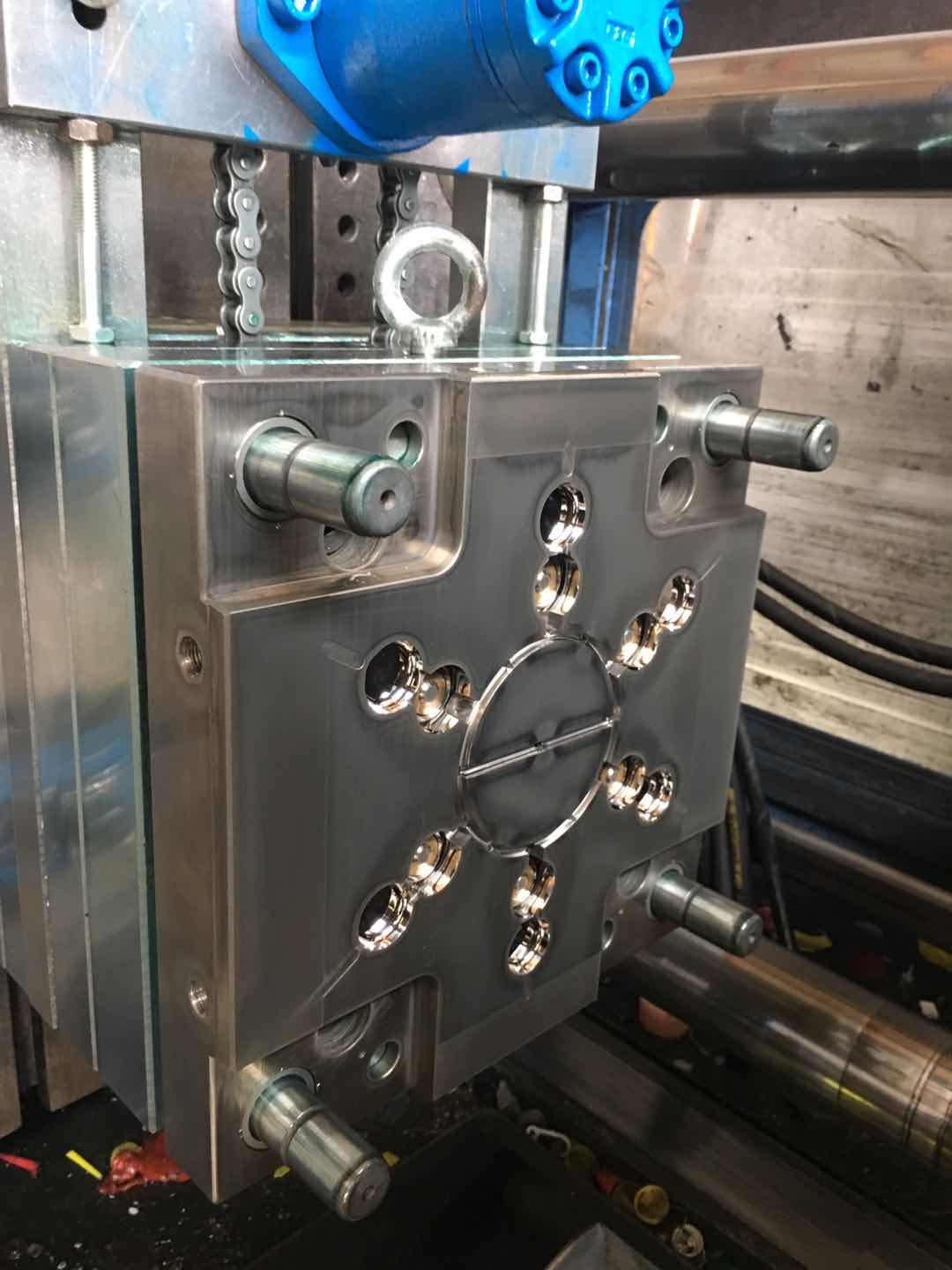

China Flip Top Cap mould,bump lotion mould and Closure mould

We are dedicated to make the quality cap mould with mould steel ,P20,H13 and S136 .and our cap mould includes:

We are dedicated to make the quality cap mould with mould steel ,P20,H13 and S136 .and our cap mould includes:

hinged closures mould

yorker spout mould

disc-top cap mould

flip-top cap mould

push-pull cap mould

twist open/close cap mould

flapper closures mould

How to design screw on a bottle flip top cap,lid and closure mould

Undercuts on the Inside of the cap

Undercuts on the Inside of the cap are usually

• Inside threads,

• snap-on ribs (for cap, closure or lids of containers), or

• major undercuts that are part of the product shape.

Inside Threads on cap

Inside threads usually occur in cap but also may be designed in many technical products such as plastic pipe hardware, etc.

The planned method of manufacture (molding, or machining after molding) should be considered.

The cap mould could be much simpler (and considerably less costly) if the cap is threaded after molding; the designer should be aware of the production quantities required.

As we stated before,it is more important to arrive at the lowest total cost product than at the most elegant method of manufacture.

If the thread must be molded, we again have two choices of how to remove the product from the core: by unscrewing or by stripping.